by Javier Copola | Jun 18, 2019 |

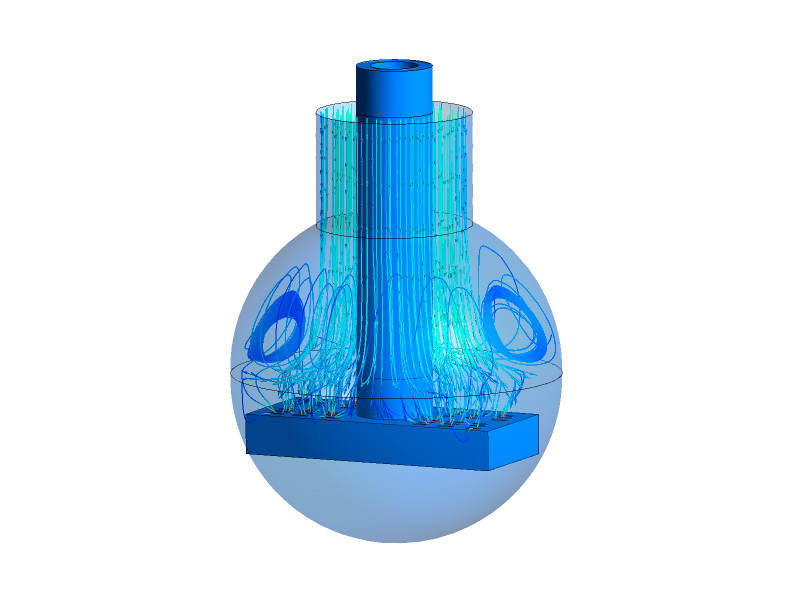

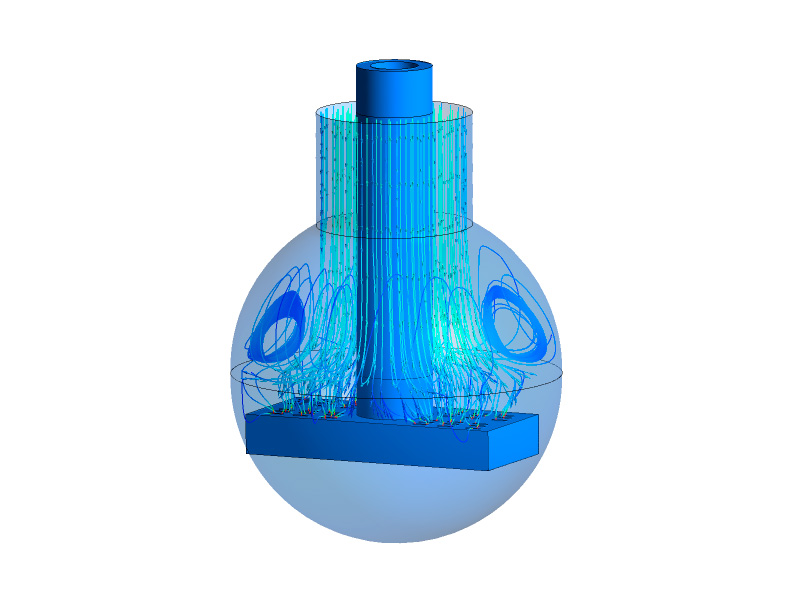

Analysis of the operation of magnetic filters.

Company: Ferrero S.A.

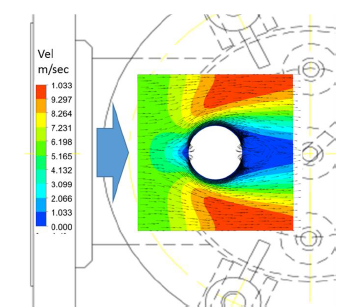

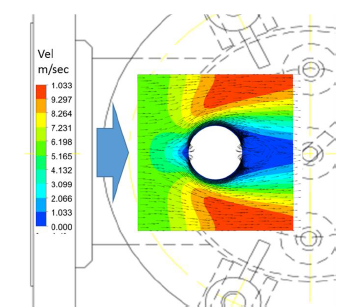

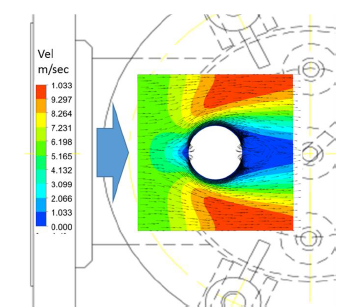

The analysis of the operation of the magnetic filters located on the production line was requested, in order to evaluate opportunities for improvement.

Magnetic filters trap ferromagnetic elements and prevent damage of the components downstream of the production line.

A first approach trought a conceptual theoretical study was carried out to determine the effectiveness of the filters to catch different particle geometries under different process conditions.

The analysis required the development of a numerical model that involves the coupling of magnetic fields and circulating flows within the filter.

by Javier Copola | Apr 9, 2019 |

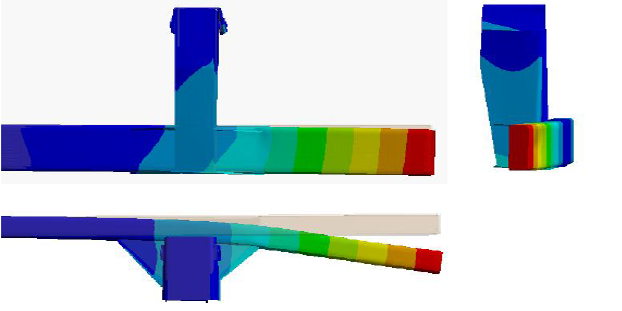

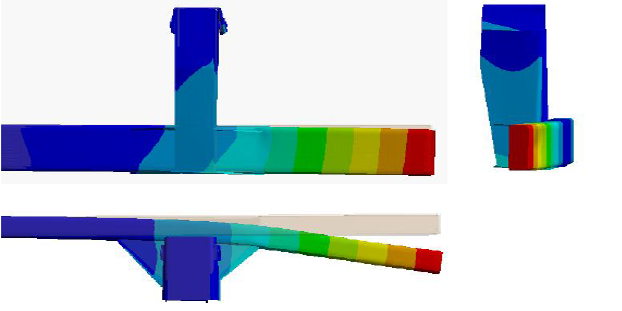

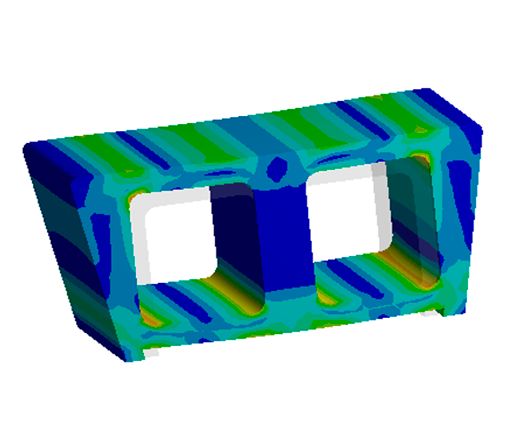

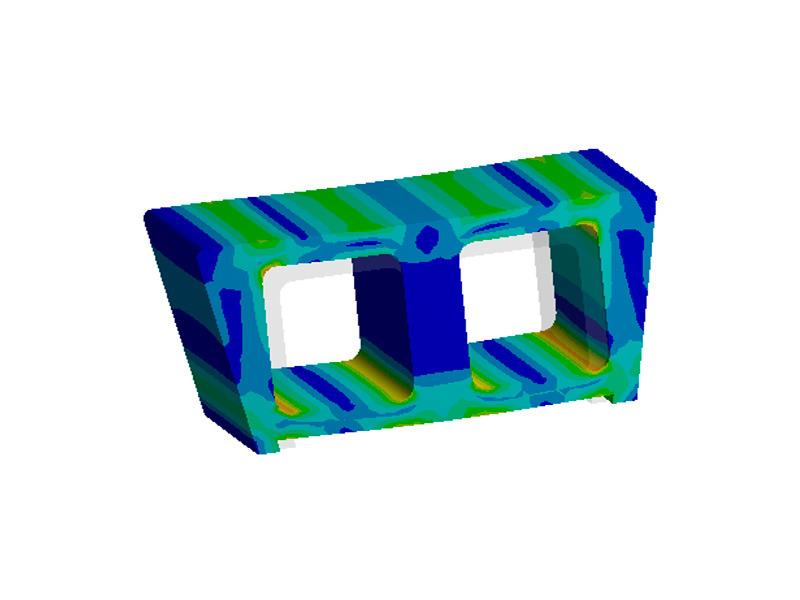

Analysis of mechanical resistance of underrun protection of trucks.

Client: Metalurgica Belgrano

Regulatory changes allow the maximum load carried by a trailer to be expanded.

The company needed to determine the ability of the underrun protection design to pass the test described in regulation No. 58 (CEPE).

The numerical modeling tools were used as verification support, allowing to computationally test the static load state specified in the regulations.

Project include:

Reproduction of laboratory load test by FEA analysis.

Numerical calculation of stress and strain under elesto-plastic regime.

Design modification in order to increase underrun protection resistance.

by Javier Copola | Sep 19, 2016 |

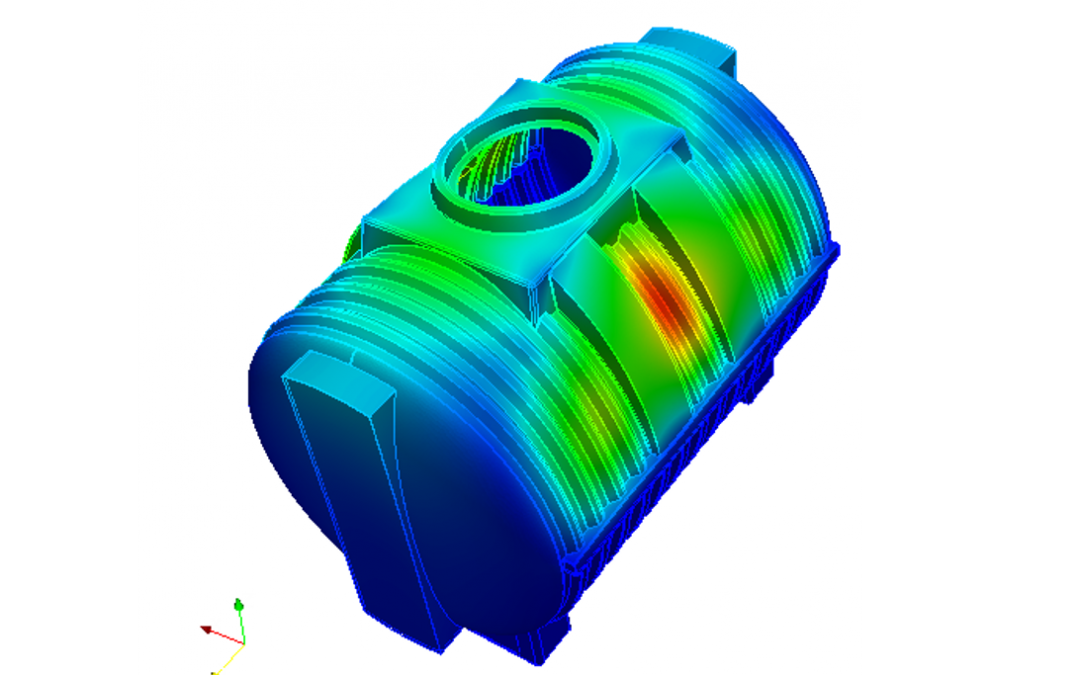

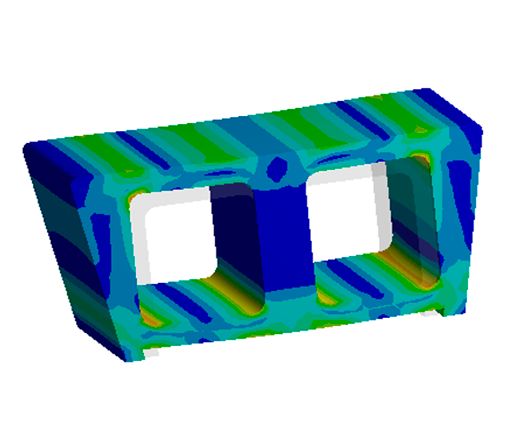

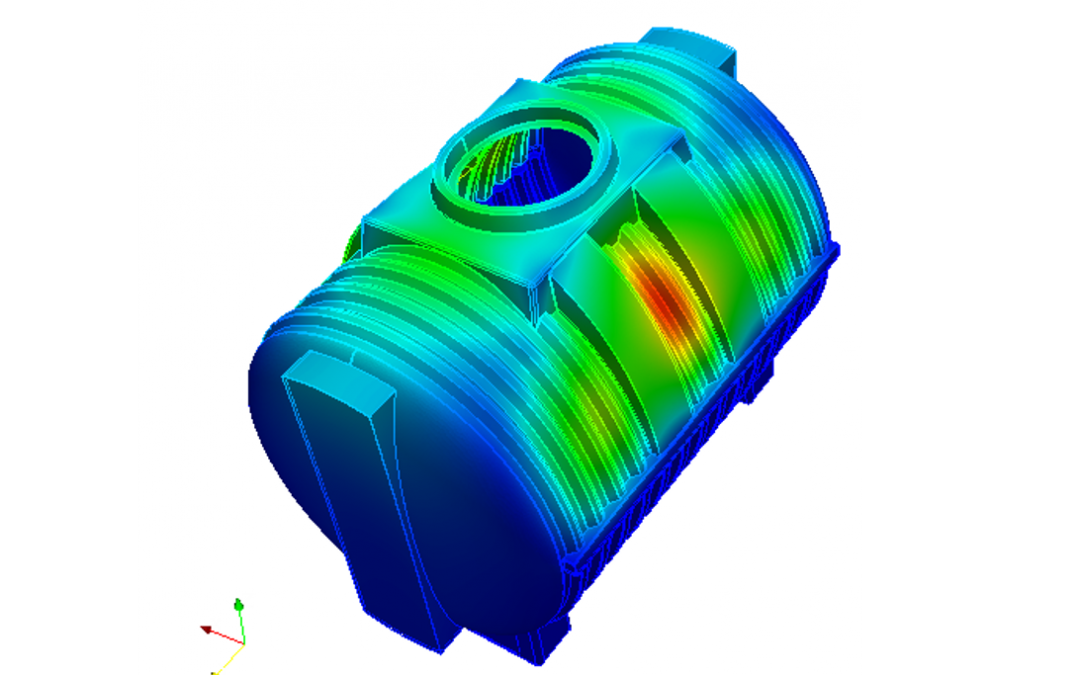

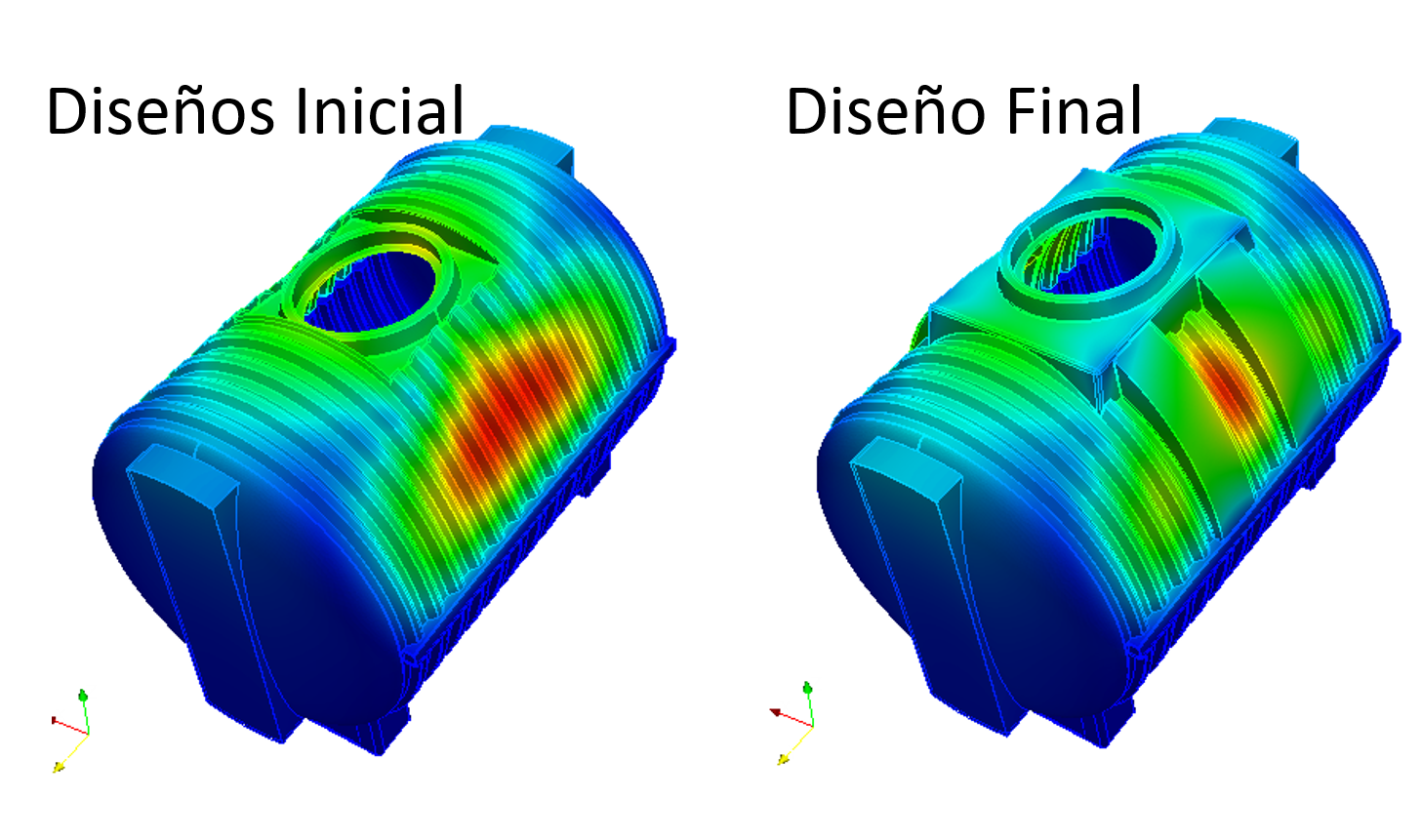

Analysis of mechanical resistance of water tank produced by rotomoulding.

Changes in the initial operating conditions of a water tank, drive to the client to request an evaluation of performance of the product.

The water tank have to operate buried and to preserve the dimensional characteristics, mechanical and functional resistance (cover opening).

Finite element analysis of the structural behavior of the cistern when buried in sand were carried out.

Results:

- the use of the numerical model allowed to analysis a variants of designs in shorter time than construct matrices, produce a prototype and test it in real conditions (trial and error procedure), representing a cost savings of 70% of the design process and considerably reducing developing time.

- a robust design was obtained that allows to buried the tank avoiding the collapse and conserving the functional characteristics (opening of the cover).

by admin_tecdesin | Nov 5, 2015 |

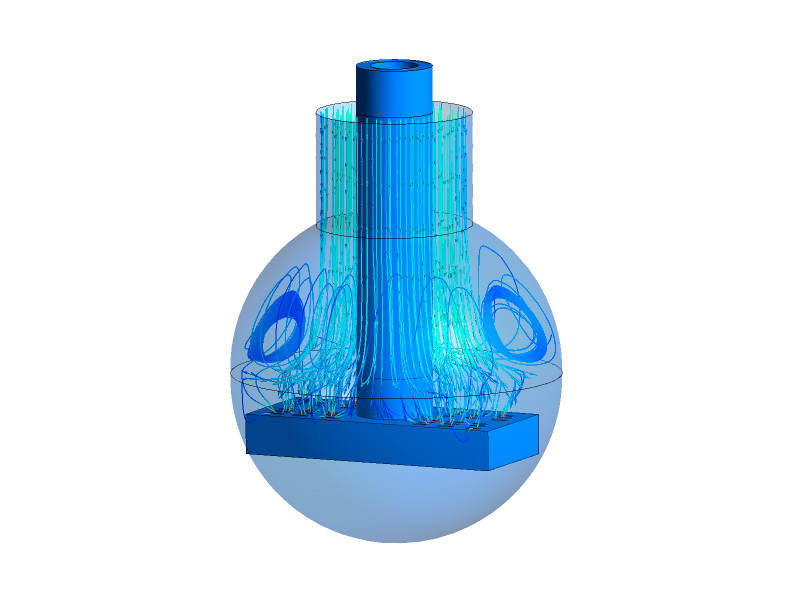

Fluidos: Filtro piscina

Optimización de dimensiones de filtros de agua con arena. Modelado del flujo de agua en medio poroso.

Se obtienen dimensiones óptimas, reduciendo costos de fabricación y aumentando vida útil del filtro.

Volver

by admin_tecdesin | Nov 5, 2015 |

Tensiones térmicas

Tensiones térmicas producidas en un ladrillo refractario al someterlo a un calentamiento uniforme.

Volver

Recent Comments