Field meassurements

Industrial measurements, Cabot Corp.

The job consisted in the execution of industrial measurements in order to understand the behavior under the thermo-mechanical stresses in the pipeline, during the actual operating conditions of the plant.

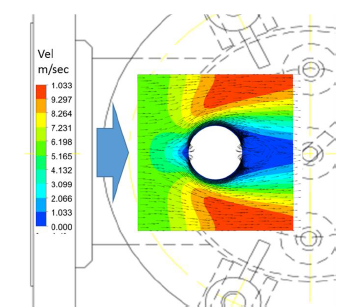

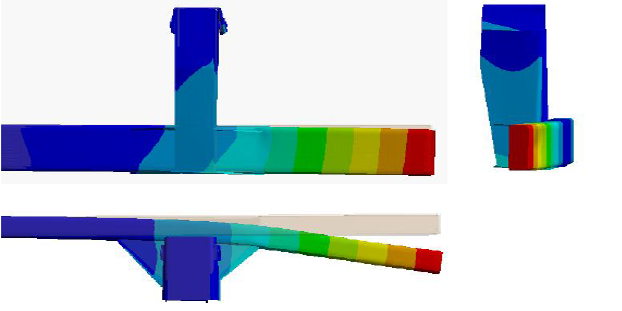

The manufacture of Black Smoke, requires circulating combustion gases through a pipe length of 20 meters and diameter 48 “(1200 mm). The walls of the stainless steel duct can reach temperatures close to 600 ° C.

In strategically selected points, thermocouples were placed that recorded the thermal gradients. The duct expansion joint was instrumented with displacement sensors, allowing a measurement of thermal deformations.

During a period of three months, temperature and displacement measurements were continuously measured every 3 seconds. The Acquisition Equipment and the sensors used are the property of TECDESIN.

The work included the analysis, interpretation of the measurements and recommendations and proposals for improvement within the Cabot plant.

Date: March-June 2017

Volver

Recent Comments